Norplex Micarta is a revolutionary material that has been making waves across various industries for its impressive durability, versatility, and performance. It’s a laminated composite material made by combining layers of paper, fabric, or other materials with thermosetting resins under high pressure and temperature. This process results in a product that boasts exceptional mechanical properties, electrical insulation capabilities, and chemical resistance. Whether you’re an engineer, designer, or simply someone curious about advanced materials, Norplex Micarta offers a fascinating glimpse into the world of modern composites.

As industries continue to evolve, the demand for high-performance materials has grown exponentially. Norplex Micarta stands out as one of the leading solutions in this space, offering a wide range of applications across aerospace, automotive, electrical, and even consumer goods sectors. Its ability to withstand extreme conditions while maintaining structural integrity makes it an ideal choice for critical components. Moreover, its customizable nature allows manufacturers to tailor its properties to specific needs, ensuring optimal performance in diverse environments.

For businesses looking to innovate and stay ahead of the competition, understanding Norplex Micarta is crucial. In this article, we’ll delve deep into its composition, manufacturing process, key characteristics, and real-world applications. We’ll also explore how it compares to other materials, address common misconceptions, and provide insights into its future potential. Whether you’re a seasoned professional or just beginning your journey into material science, this guide will equip you with everything you need to know about Norplex Micarta.

Read also:Does Walmart Take American Express

Table of Contents

- 1. What Exactly is Norplex Micarta?

- 2. How is Norplex Micarta Manufactured?

- 3. Why Choose Norplex Micarta Over Other Materials?

- 4. Can Norplex Micarta Be Used in Extreme Conditions?

- 5. Key Applications of Norplex Micarta

- 6. What Are the Advantages of Using Norplex Micarta?

- 7. Potential Drawbacks and Limitations

- 8. Is Norplex Micarta Environmentally Friendly?

- 9. Frequently Asked Questions

- 10. Conclusion

What Exactly is Norplex Micarta?

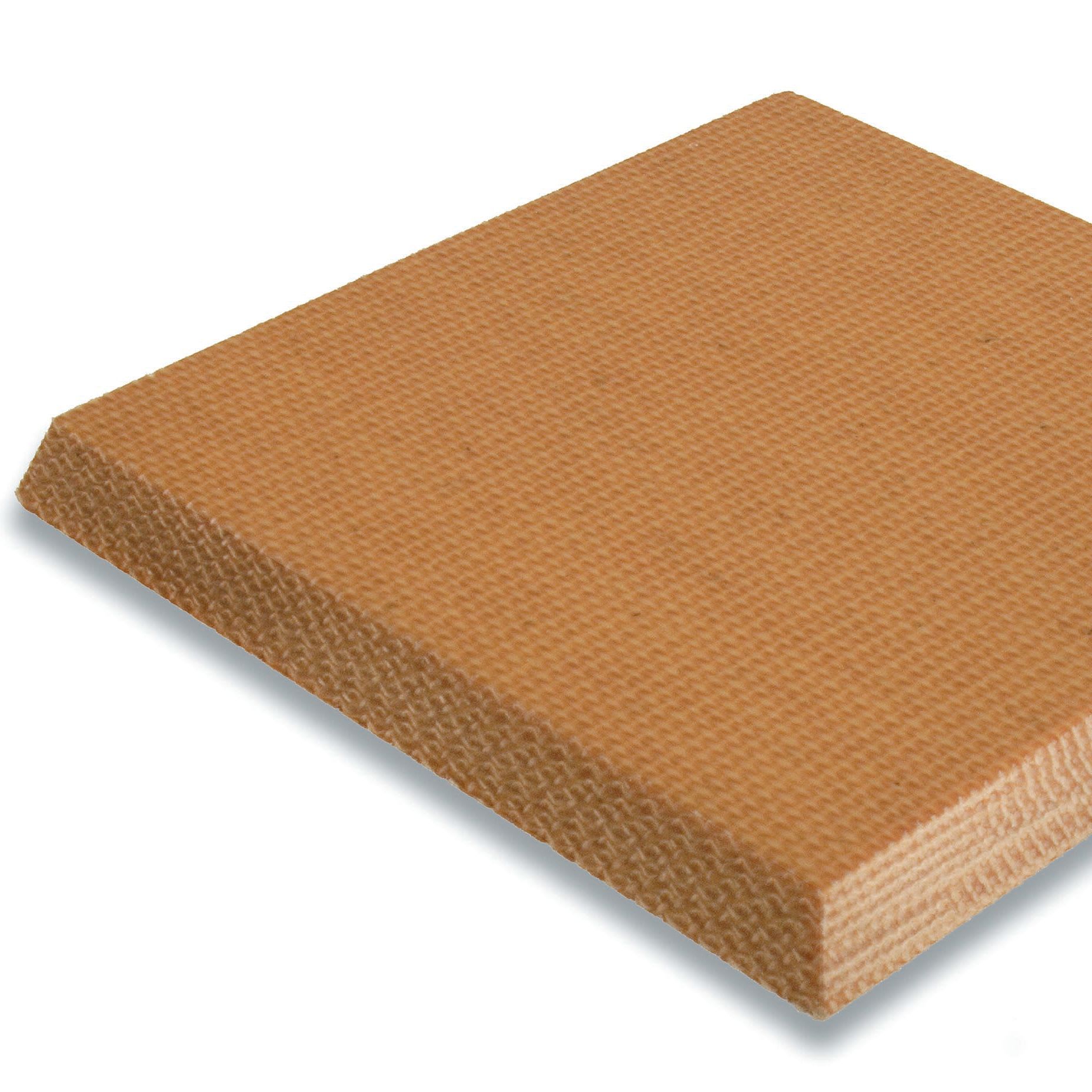

Norplex Micarta is a type of laminated composite material that belongs to the broader family of Micarta products. The term “Micarta” itself refers to a group of materials developed by combining layers of various substrates—such as paper, cotton, linen, or fiberglass—with thermosetting resins like phenolic, epoxy, or melamine. These materials are then subjected to intense heat and pressure, creating a dense, durable composite with outstanding physical and chemical properties.

The name "Norplex Micarta" specifically denotes a range of products manufactured by Norplex-Micarta, a leading company in the composites industry. These materials are engineered to meet stringent industry standards and offer tailored solutions for different applications. For example, some variations of Norplex Micarta are designed for high-temperature environments, while others focus on electrical insulation or mechanical strength.

One of the defining features of Norplex Micarta is its versatility. Depending on the substrate and resin combination, it can exhibit a wide range of properties, from exceptional hardness and wear resistance to excellent electrical conductivity. This adaptability makes it suitable for use in everything from precision machinery to everyday household items.

How Does Norplex Micarta Differ From Other Composites?

While there are many composite materials available today, Norplex Micarta sets itself apart through its unique blend of performance characteristics. Unlike metals, which can corrode or degrade over time, Norplex Micarta maintains its integrity even in harsh conditions. Additionally, compared to plastics, it offers superior strength and dimensional stability. These advantages make it a preferred choice in industries where reliability and longevity are paramount.

How is Norplex Micarta Manufactured?

The manufacturing process of Norplex Micarta involves several intricate steps that ensure its superior quality and performance. It begins with the selection of raw materials, including the substrate (e.g., paper, fabric, or fiberglass) and the thermosetting resin. These materials are carefully chosen based on the desired properties of the final product.

Once the materials are prepared, they are layered together in a controlled manner. Each layer is impregnated with the resin, ensuring uniform distribution and adhesion. The stack of layers is then placed in a hydraulic press, where it is subjected to extreme heat and pressure. This process, known as hot pressing, causes the resin to cure and bind the layers together, forming a solid composite.

Read also:Simarjeet Singh

After pressing, the material undergoes additional processing steps, such as cooling, cutting, and finishing, to achieve the desired dimensions and surface quality. Throughout the manufacturing process, strict quality control measures are implemented to ensure consistency and compliance with industry standards.

What Factors Influence the Properties of Norplex Micarta?

The properties of Norplex Micarta are influenced by several key factors, including the type of substrate used, the resin composition, and the processing conditions. For instance, using fiberglass as the substrate can enhance the material’s strength and stiffness, while paper-based substrates may result in greater flexibility. Similarly, varying the resin formulation can alter the material’s thermal and electrical characteristics.

Why Choose Norplex Micarta Over Other Materials?

Selecting the right material for a given application is critical to achieving optimal performance and cost-effectiveness. Norplex Micarta offers several compelling reasons why it should be considered over alternative options. First and foremost, its exceptional durability ensures long-term reliability, reducing the need for frequent replacements and maintenance. Additionally, its ability to withstand extreme temperatures, chemicals, and mechanical stress makes it well-suited for demanding environments.

Beyond its functional attributes, Norplex Micarta also provides economic benefits. Its lightweight nature allows for easier handling and transportation, while its customizable properties enable manufacturers to optimize their designs for specific applications. Furthermore, its resistance to wear and tear translates to extended service life, ultimately saving costs in the long run.

What Industries Benefit Most From Norplex Micarta?

A wide array of industries benefit from the use of Norplex Micarta. In aerospace, it is employed in the production of aircraft components due to its lightweight and high-strength characteristics. The automotive sector leverages its electrical insulation properties for wiring harnesses and other electrical systems. Meanwhile, the electrical industry relies on its dielectric capabilities for switchgear and transformer components. Consumer goods manufacturers also utilize Norplex Micarta for its aesthetic appeal and durability in products like kitchenware and musical instruments.

Can Norplex Micarta Be Used in Extreme Conditions?

Yes, Norplex Micarta is specifically designed to perform exceptionally well in extreme conditions. Whether it’s enduring high temperatures, withstanding corrosive chemicals, or resisting mechanical stress, this material has proven its mettle time and again. Its robust composition ensures that it remains stable and functional even under the harshest circumstances.

For example, in the oil and gas industry, Norplex Micarta is often used for valve seats and seals, where it must contend with high-pressure fluids and aggressive chemicals. Similarly, in the defense sector, it is utilized in armor plating and weapon components, where its ability to absorb impact and resist abrasion is crucial.

Which Variants of Norplex Micarta Are Best Suited for Extreme Environments?

Some variants of Norplex Micarta are specifically engineered for extreme conditions. For instance, grades containing fiberglass substrates and epoxy resins are ideal for applications requiring high thermal stability and mechanical strength. On the other hand, phenolic-based grades excel in environments where chemical resistance and wear resistance are priorities.

Key Applications of Norplex Micarta

The versatility of Norplex Micarta enables it to find applications across a multitude of industries. In the aerospace sector, it is used for structural components, interior panels, and engine parts. The automotive industry employs it in braking systems, electrical components, and body panels. Electrical manufacturers rely on it for insulators, busbars, and switchgear components. Meanwhile, consumer goods companies utilize it for kitchen utensils, guitar fingerboards, and decorative items.

Beyond these traditional applications, Norplex Micarta is also gaining traction in emerging fields such as renewable energy and medical devices. Its ability to meet the specific demands of these industries highlights its adaptability and innovation potential.

What Are Some Emerging Applications for Norplex Micarta?

As technology advances, new opportunities for Norplex Micarta continue to emerge. In the renewable energy sector, it is being explored for wind turbine blades and solar panel components due to its lightweight and durable nature. In the medical field, its biocompatibility and sterilization resistance make it a promising candidate for surgical instruments and implants.

What Are the Advantages of Using Norplex Micarta?

Using Norplex Micarta offers numerous advantages that contribute to its widespread adoption. Its exceptional durability ensures that products made from it remain functional for extended periods, minimizing downtime and maintenance costs. Its customizable properties allow for tailored solutions that meet specific application requirements, enhancing overall performance. Additionally, its lightweight nature improves efficiency in applications where weight reduction is a priority.

From an environmental perspective, Norplex Micarta’s longevity reduces the need for resource-intensive replacements, promoting sustainability. Its recyclability further aligns with eco-friendly practices, making it an attractive option for companies committed to reducing their carbon footprint.

How Does Norplex Micarta Compare to Traditional Materials?

Compared to traditional materials like metals and plastics, Norplex Micarta offers several key advantages. Unlike metals, it does not corrode or rust, ensuring consistent performance over time. Unlike plastics, it provides superior strength and dimensional stability, making it more reliable in critical applications. These differences highlight Norplex Micarta’s superiority in terms of both functionality and longevity.

Potential Drawbacks and Limitations

While Norplex Micarta boasts numerous advantages, it is not without its limitations. One potential drawback is its relatively high cost compared to some traditional materials. This can be a barrier for budget-conscious projects or applications where cost is a primary concern. Additionally, its fabrication process may require specialized equipment and expertise, adding complexity to manufacturing operations.

Another limitation lies in its brittleness under certain conditions. While it is generally strong and durable, excessive impact or flexing can lead to cracking or failure. Therefore, careful consideration of application requirements is essential to ensure its suitability.

Are There Workarounds for Norplex Micarta’s Limitations?

Yes, many of Norplex Micarta’s limitations can be addressed through proper design and engineering practices. For instance, incorporating additional reinforcements or modifying the substrate-resin combination can enhance its impact resistance. Similarly, optimizing processing parameters during manufacturing can improve its overall performance and reduce the risk of failure.

Is Norplex Micarta Environmentally Friendly?

The environmental impact of Norplex Micarta depends on various factors, including its composition, manufacturing process, and end-of-life disposal. While the material itself is not inherently harmful, its production does involve the use of resins and other chemicals that may raise environmental concerns. However, advancements in sustainable manufacturing practices and recycling technologies are helping to mitigate these effects.

Furthermore, the extended service life and recyclability of Norplex Micarta contribute to its eco-friendly profile. By reducing the frequency of replacements and promoting resource efficiency, it supports a more sustainable approach to material usage.

What Steps Are Being Taken to Improve Norplex Micarta’s Environmental Impact?

Manufacturers are increasingly focusing on developing greener alternatives and improving existing processes to enhance Norplex Micarta’s environmental performance. This includes exploring bio-based resins, optimizing energy consumption during production, and implementing closed-loop recycling systems. These efforts aim to create a more sustainable future for composite materials while maintaining their exceptional performance characteristics.

Frequently Asked Questions

1. Is Norplex Micarta Expensive?

While Norplex Micarta can be more expensive than some traditional materials, its long-term benefits often justify the initial investment. Its durability, customizability, and performance advantages can lead to significant cost savings over time.

2. Can Norplex Micarta Be Recycled?

Yes, Norplex Micarta can be recycled through specialized processes. However, the feasibility of recycling depends on the specific grade and composition of the material. Efforts are ongoing to improve recycling technologies and make them more widely accessible.

3. What Industries Use Norplex Micarta Most?

Norplex Micarta is most commonly used in aerospace, automotive, electrical, and consumer goods industries. Its versatility and performance capabilities make it an ideal choice for a wide range of applications across these sectors.

Conclusion

Norplex Micarta represents a remarkable advancement in material science, offering unparalleled performance and versatility for a variety of applications. From its robust manufacturing process to its impressive range of properties, it continues to redefine what’s possible in the world of composites. As industries evolve and demand for high-performance materials grows, Norplex Micarta is poised to play an increasingly important role in shaping the future of innovation.

Whether you’re an engineer seeking reliable solutions, a designer exploring new possibilities, or simply someone curious about cutting-edge materials, Norplex Micarta provides a wealth of opportunities. By understanding its composition, capabilities, and limitations, you can harness its full potential to drive success in your projects and beyond.